CNC Center Marks

- General Overview

- Tips and Tricks

- Related Tools

Show CNC marks on member details: ![]() or

or ![]() .

.

If this box is checked (

), then CNC marks (represented as X's) will be shown on member details that subsequently undergo Detail Members.

If the box is not checked (

), CNC marks will still be generated and can still be CNC downloaded. They will continue to be displayed in Modeling, and they will continue to be dimensioned on submaterial details. They just won't be shown on member details.

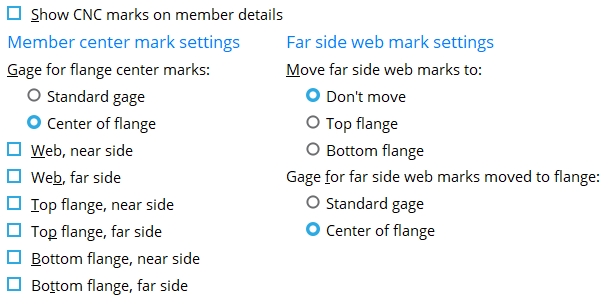

Member center mark settings

Gage for flange center marks: Standard gage or Center of flange.

|

In both examples, Top flange, near side is checked. Center of flange is selected for the top example. Standard gage is selected for the bottom example. |

Standard gage specifies that the mark be on the normal gage line of the member. CNC Center Marks uses the standard gage as specified in the local shape file

Center of flange specifies that the mark be on the center line of the desired flange.

If this box is checked (

), a CNC mark is placed on the center of the near side of the web of a member's main material.

If the box is not checked (

), a CNC mark is not automatically placed at this location.

If this box is checked (

), a CNC mark is placed on the center of the far side of the web of the member (or the mark may be moved or not moved to the top/bottom flange depending on the selection made to Move far side web marks to).

If this box is not checked (

), a CNC mark is not automatically placed at this location.

If this box is checked (

), a CNC mark is placed on the top flange of a member. Depending on whether Center of flange or Standard gage has been selected for Gage for flange center marks, the mark is placed on the center line of the top flange, or it is placed on the standard gage line on the near side of the top flange.

If this box is not checked (

), a CNC mark is not automatically placed at this location.

If this box is checked (

), a CNC mark is placed on the center of the far side of the top flange of a member.

If this box is not checked (

), a CNC mark is not be automatically placed at this location.

Bottom flange, near side: ![]() or

or ![]() .

.

If this box is checked (

), a CNC mark is placed on the center of the near side of the bottom flange of a member. Depending on whether Center of flange or Standard gage has been selected for Gage for flange center marks, the mark is either on the center line of the bottom flange or on the standard gage line on the near side of the bottom flange.

If this box is not checked (

), a CNC mark is not automatically placed at this location.

If this box is checked (

), a CNC mark is placed on the center of the far side of the bottom flange of a member.

If this box is not checked (

), a CNC mark is not automatically placed at this location.

Far side web mark settings

Move far side web marks to: Don't move or Top flange or Bottom flange. This applies when Web, far side is checked.

Don't move places far side web marks on the far side web. This means that CNC machines that do not have far side marking tools will require the material to be flipped in order to replicate the mark.

Top flange moves far side web marks to the top flange. For example, you might set this to Top flange as an alternative to manually flipping the member over in order for the marks to be made on that side.

Bottom flange moves far side web marks to the bottom flange.

Gage for far side web marks moved to flange: Standard gage or Center of flange. This applies when Web, far side is checked and Move far side web marks to is set to Top flange or Bottom flange.

Standard gage sets the mark to be placed on normal gage line of the flange as specified in the local shape file.

Center of flange sets the far side mark be moved to the center line of the desired flange.

|

|

OK (or the Enter key) closes this screen and applies the settings.

Cancel (or the Esc key) closes this screen without saving any changes.

Reset undoes all changes made to this screen since you first opened it. The screen remains open.

- CNC marks (materials are marked with based on this window)

- Process & Create Solids (when selections are applied)

- Add 3D Hole (alternative to automatic center marking)

- CNC Module (to download marks to a CNC machine)